gords1001

Achiever

- Joined

- Oct 12, 2013

- Messages

- 2,031

I didn't take many pictures tonight, I wanted to make sone head way and get this done and out of the way as the dna20 no longer interests me.

The original plan was to power this with a 6000mah feilong 32650 I have lying around and build up a chassis out of a nice piece of timber and some brass.

The problem is, I'm vaping at 25watts or more on my day to day mechs, so I'm back to the issue of vw not really cutting it for me.

Having been chatting with some like minded lunatics, there are other plans now afoot, but it did leave me with the dilemma of a £45 board lying about in need of a home.

Anyway I got a bee in my bonnet today and decided to start looking at things. I still have a tobacco tin that will take an 18650 battery case, and B1mble sent me some bits down in an altoids tin at Christmas.......

A quick test fit and the dna20, 18650 case both fit in and leave room for micro switches, 510 connector and wiring, game on.

So, I've got a bit of the drilling and cutting done, concluded I need another small micro switch for the firing button as the big anti vandal switch wont fit and wrote off the 510 connector, I wasn't all that impressed with it anyway so I'll look at building something for that, but I did get the battery tray ready for gluing up so here's the start of my first build, I'll update when I've made further progress, which will likely be when I've aquired more parts, although I will get the tin fully drilled ready for the required bits.

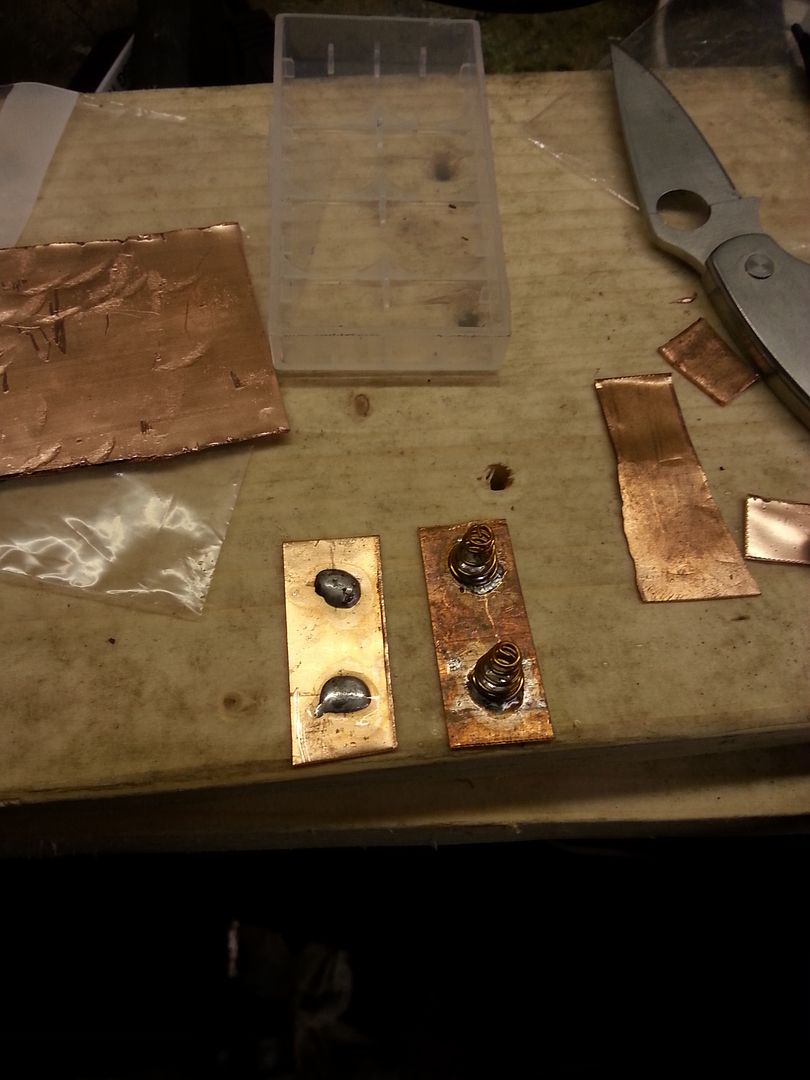

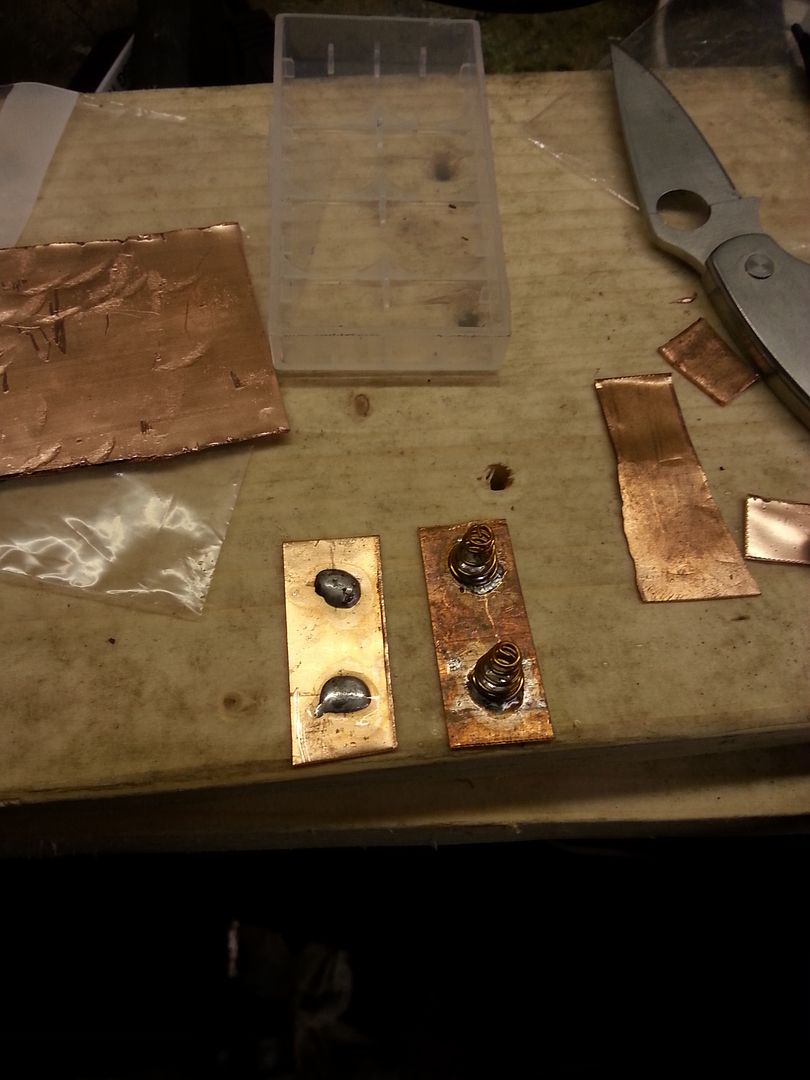

So, the tray. I had a broken 18650 case lying about, I drcided this would be a good home for it, it will be epoxied into the altoids tin when I know everything works and the top will just push on to insulate the cell connections.

There's the pos and neg contacts, note the bumps to allow flat top cells, the 20g silicon cables have been passed through a small hole drilled in the top corner of each plate, twisted and soldered in place.

Here's a mock up of the tray, ready for the plates being epoxied in place.

Ok so I grabbed a couple of shots to give an idea of my plan.

So here's the tin and dna20 (yes, if you have not seen one, their pretty freaking small, not quite a nanjg105c's diminutive size but small none the less).

This gives a general idea of layout. Battery tray (correct term here for the pedants like me, its an array of celks which makes a battery) will be epoxied down and the top cover will lift off for cell replacement and be refitted to idolate those copper plates, dna down the botton, moving up the side from the display will be buttons down up fire. 510 connector will go on the top sandwiching the top edge of the tin to make a hopefully rigid connector.

The original plan was to power this with a 6000mah feilong 32650 I have lying around and build up a chassis out of a nice piece of timber and some brass.

The problem is, I'm vaping at 25watts or more on my day to day mechs, so I'm back to the issue of vw not really cutting it for me.

Having been chatting with some like minded lunatics, there are other plans now afoot, but it did leave me with the dilemma of a £45 board lying about in need of a home.

Anyway I got a bee in my bonnet today and decided to start looking at things. I still have a tobacco tin that will take an 18650 battery case, and B1mble sent me some bits down in an altoids tin at Christmas.......

A quick test fit and the dna20, 18650 case both fit in and leave room for micro switches, 510 connector and wiring, game on.

So, I've got a bit of the drilling and cutting done, concluded I need another small micro switch for the firing button as the big anti vandal switch wont fit and wrote off the 510 connector, I wasn't all that impressed with it anyway so I'll look at building something for that, but I did get the battery tray ready for gluing up so here's the start of my first build, I'll update when I've made further progress, which will likely be when I've aquired more parts, although I will get the tin fully drilled ready for the required bits.

So, the tray. I had a broken 18650 case lying about, I drcided this would be a good home for it, it will be epoxied into the altoids tin when I know everything works and the top will just push on to insulate the cell connections.

There's the pos and neg contacts, note the bumps to allow flat top cells, the 20g silicon cables have been passed through a small hole drilled in the top corner of each plate, twisted and soldered in place.

Here's a mock up of the tray, ready for the plates being epoxied in place.

Ok so I grabbed a couple of shots to give an idea of my plan.

So here's the tin and dna20 (yes, if you have not seen one, their pretty freaking small, not quite a nanjg105c's diminutive size but small none the less).

This gives a general idea of layout. Battery tray (correct term here for the pedants like me, its an array of celks which makes a battery) will be epoxied down and the top cover will lift off for cell replacement and be refitted to idolate those copper plates, dna down the botton, moving up the side from the display will be buttons down up fire. 510 connector will go on the top sandwiching the top edge of the tin to make a hopefully rigid connector.

Last edited: