Bigwhiterabbitt

Postman

- Joined

- Apr 6, 2013

- Messages

- 126

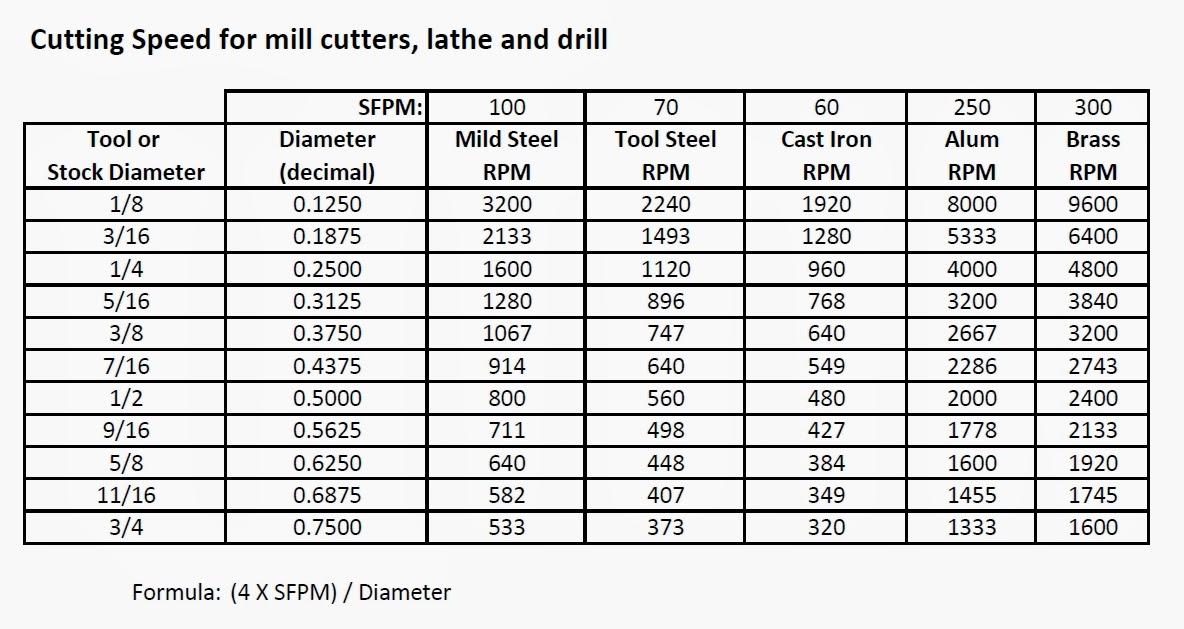

Slowly starting to learn what I can and can't do (can do it its just a bit harder lol..). I know if I want to drill a larger hole in aluminium I need to drill a smaller hole 1st but how far do you take this? For example if I'm drilling say a 5mm hole do I need to go smaller 1st to stop the drill wandering etc..?