This guide is based on building a Kanger head which are used in Protanks/Evods/Davides etc etc

Tools required:

1 x 2mm jewellers screwdriver

1 x Nail Clippers

1 x Flat nose tweezers

1 x Pin point tweezers

1 x Pliers

1 x 14 gauge Blunt Needle

1 x 0.25 Kanthal

1 x Blowtorch or Lighter

1 x Organic cotton wool

Before starting make sure your hands are clean as anything on them like grease etc will be going onto the wire and cotton.....you don't want that.

Step 1: Get some 0.25 Kanthal wire, around 14cm of it and heat it up until red, takes seconds and it also takes the springiness away from the coil.

Step 2: Wrap the coil around the 2mm jewellers screwdriver nice and tight around the edge of the screwdriver (i do around 10 turns, this should give about 2.2 ohms resistance) and then push all coils very close together with your fingers towards the jewellers screwdrivers edge so they are nice and snug next to each other and keep holding the legs tight at the same time, the legs at the end of the coil should be facing the same way as each other, facing you when finished wrapping.

Step 3: Gently pull the coil off the jewellers screwdriver and at the same time holding the legs of the wire place into the tip of a pair of tweezers (preferably flat tweezers).

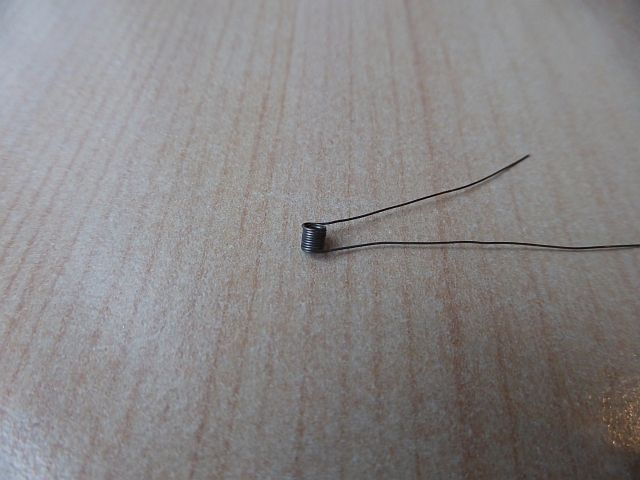

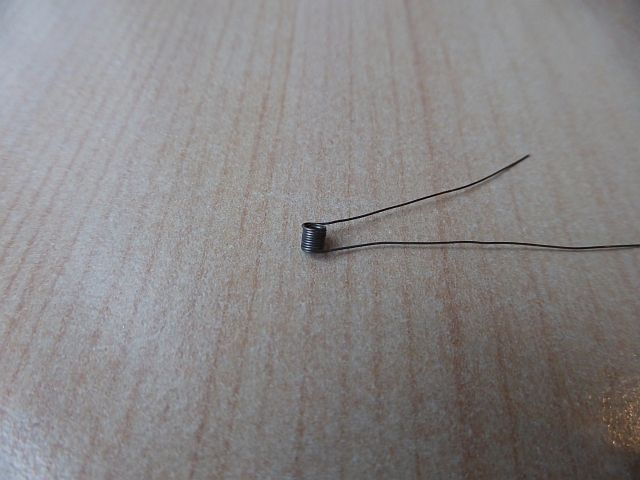

Step 4: Once all held in place in the tweezers flame the coil until red hot and hold tight with the tweezers until cool, do this a couple of times....should end up looking like this:

Step 5: Place the 14 gauge Blunt Needle into the centre of the coil.

Step 6: Feed the coil legs through the centre of the head and place the 14 gauge Blunt Needle/Coil right down too the bottom of the slits of the head, You now have two wires sticking out the end of the head, one is positive, the other negative.

Step 7: Take one of the wires (does not matter which one) and pull tight and bend over the edge of the head rim.

Step 8: Get the other wire and slide the wire through the centre of the rubber bung and fit the rubber bung into place on the head.

Step 9: Now pull the wire that is in the centre of the rubber bung and pull and bend to the edge of the rubber bung.

Step 10: Now get the metal centre pin and push inside the rubber bung.

Step 11: Now all is in place get each wire and wiggle them until they snap, this gives a nice clean snap of both wires.

Step 12: Now that all wires are in place remove the 14 gauge Blunt Needle from the coil, You should now have a coil that is sturdy and in place on the head.

Step 13: Place the head into a device that can check resistance to make sure all is fine, (Optional: i normally when doing this dry burn the coil a few times to burn of any impurities that may remain on the coil)

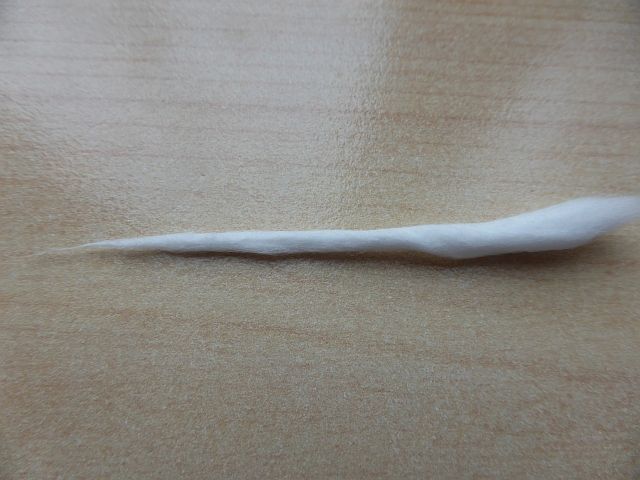

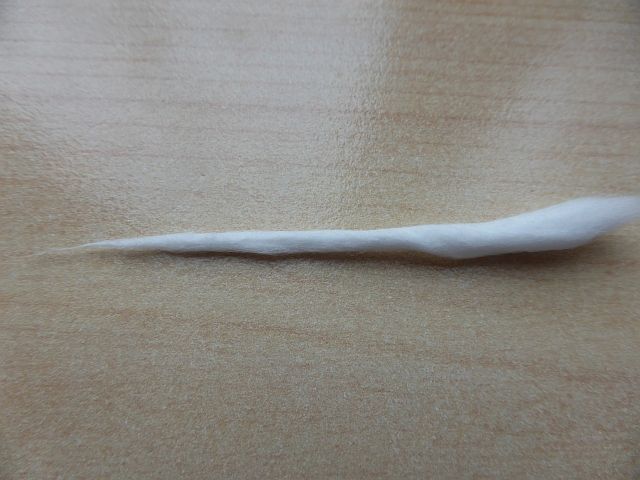

Step 14: Now get some cotton wool and pull apart a bit that will be enough for the wick, not too much and not too less....this bit is by judgement so you need to guess right, If you use too much cotton the coil will strangle it and it won't wick fast enough, if you use to little it will wick too fast and you may get leaks, Get the cotton and roll into a tube, not too tight and not too loose.

Step 15: Thread the cotton through the microcoil, it should not be too easy and not too hard to pull through (this normally determines whether you have made the right thickness of the cotton) Once all done make sure the coil is still in the centre of the head above the air hole, if not adjust with your tweezers.

Step 16: Once all threaded and you are happy with it, trim the ends of the cotton too the edge of the head:

Step 17: Optional: Soak the cotton wick with your chosen juice to speed up the wicking process up.

Step 18: Fill your chosen tank and leave to rest for 3-5 minutes

Step 19: Do some dry pulls to get things all working.

Step 20: Vape away

Removing the old cotton and cleaning the coil:

Step 1: Take the head from the atty and hold in one hand.

Step 2: Using tweezers or small pliers just pick little strands of cotton away, don't try and pull the whole of the cotton out in one go as it won't happen due to the cotton expanding from juice and you will put too much of a strain on the coil.

Step 3: Keep pulling little strands until there is enough room for the rest of the cotton to come out in one hit.

Step 4: If the coil has moved away from the center don't worry, just get your tweezers and move it back to the center.

Step 5: Optional: Once all cotton is removed i normally give the head a little wash and blow through the top of the head so any water will come out of the bottom and then throughlly pat dry

Step 6: Put the head onto a device to make sure all is still working well, i.e resistance.

Step 7: Pulse the coil for about 2-3 seconds at a time just to dry out the coil, do this about 3-4 times, then pulse the coil until red hot and then when it has cooled a bit blow off any resideue, keep doing this until it looks like new again.

Step 8: Repeat steps 14 too 20

Hope this helps

Tools required:

1 x 2mm jewellers screwdriver

1 x Nail Clippers

1 x Flat nose tweezers

1 x Pin point tweezers

1 x Pliers

1 x 14 gauge Blunt Needle

1 x 0.25 Kanthal

1 x Blowtorch or Lighter

1 x Organic cotton wool

Before starting make sure your hands are clean as anything on them like grease etc will be going onto the wire and cotton.....you don't want that.

Step 1: Get some 0.25 Kanthal wire, around 14cm of it and heat it up until red, takes seconds and it also takes the springiness away from the coil.

Step 2: Wrap the coil around the 2mm jewellers screwdriver nice and tight around the edge of the screwdriver (i do around 10 turns, this should give about 2.2 ohms resistance) and then push all coils very close together with your fingers towards the jewellers screwdrivers edge so they are nice and snug next to each other and keep holding the legs tight at the same time, the legs at the end of the coil should be facing the same way as each other, facing you when finished wrapping.

Step 3: Gently pull the coil off the jewellers screwdriver and at the same time holding the legs of the wire place into the tip of a pair of tweezers (preferably flat tweezers).

Step 4: Once all held in place in the tweezers flame the coil until red hot and hold tight with the tweezers until cool, do this a couple of times....should end up looking like this:

Step 5: Place the 14 gauge Blunt Needle into the centre of the coil.

Step 6: Feed the coil legs through the centre of the head and place the 14 gauge Blunt Needle/Coil right down too the bottom of the slits of the head, You now have two wires sticking out the end of the head, one is positive, the other negative.

Step 7: Take one of the wires (does not matter which one) and pull tight and bend over the edge of the head rim.

Step 8: Get the other wire and slide the wire through the centre of the rubber bung and fit the rubber bung into place on the head.

Step 9: Now pull the wire that is in the centre of the rubber bung and pull and bend to the edge of the rubber bung.

Step 10: Now get the metal centre pin and push inside the rubber bung.

Step 11: Now all is in place get each wire and wiggle them until they snap, this gives a nice clean snap of both wires.

Step 12: Now that all wires are in place remove the 14 gauge Blunt Needle from the coil, You should now have a coil that is sturdy and in place on the head.

Step 13: Place the head into a device that can check resistance to make sure all is fine, (Optional: i normally when doing this dry burn the coil a few times to burn of any impurities that may remain on the coil)

Step 14: Now get some cotton wool and pull apart a bit that will be enough for the wick, not too much and not too less....this bit is by judgement so you need to guess right, If you use too much cotton the coil will strangle it and it won't wick fast enough, if you use to little it will wick too fast and you may get leaks, Get the cotton and roll into a tube, not too tight and not too loose.

Step 15: Thread the cotton through the microcoil, it should not be too easy and not too hard to pull through (this normally determines whether you have made the right thickness of the cotton) Once all done make sure the coil is still in the centre of the head above the air hole, if not adjust with your tweezers.

Step 16: Once all threaded and you are happy with it, trim the ends of the cotton too the edge of the head:

Step 17: Optional: Soak the cotton wick with your chosen juice to speed up the wicking process up.

Step 18: Fill your chosen tank and leave to rest for 3-5 minutes

Step 19: Do some dry pulls to get things all working.

Step 20: Vape away

Removing the old cotton and cleaning the coil:

Step 1: Take the head from the atty and hold in one hand.

Step 2: Using tweezers or small pliers just pick little strands of cotton away, don't try and pull the whole of the cotton out in one go as it won't happen due to the cotton expanding from juice and you will put too much of a strain on the coil.

Step 3: Keep pulling little strands until there is enough room for the rest of the cotton to come out in one hit.

Step 4: If the coil has moved away from the center don't worry, just get your tweezers and move it back to the center.

Step 5: Optional: Once all cotton is removed i normally give the head a little wash and blow through the top of the head so any water will come out of the bottom and then throughlly pat dry

Step 6: Put the head onto a device to make sure all is still working well, i.e resistance.

Step 7: Pulse the coil for about 2-3 seconds at a time just to dry out the coil, do this about 3-4 times, then pulse the coil until red hot and then when it has cooled a bit blow off any resideue, keep doing this until it looks like new again.

Step 8: Repeat steps 14 too 20

Hope this helps

I've got about 6 or 7 kanger atty heads waiting to be recoiled, I shall do just this.

I've got about 6 or 7 kanger atty heads waiting to be recoiled, I shall do just this.