Hi Guys --

Been playing with Autocad Fusion and my 3d printer and have been designing some hybrid billet box/Aspire boxx type designs using 21700 batteries. The original and clone billet box is aluminum and uses the chasis for ground so screwing in the "nut" provides ground for the atomizer. Pretty neat design the more I thought about it.

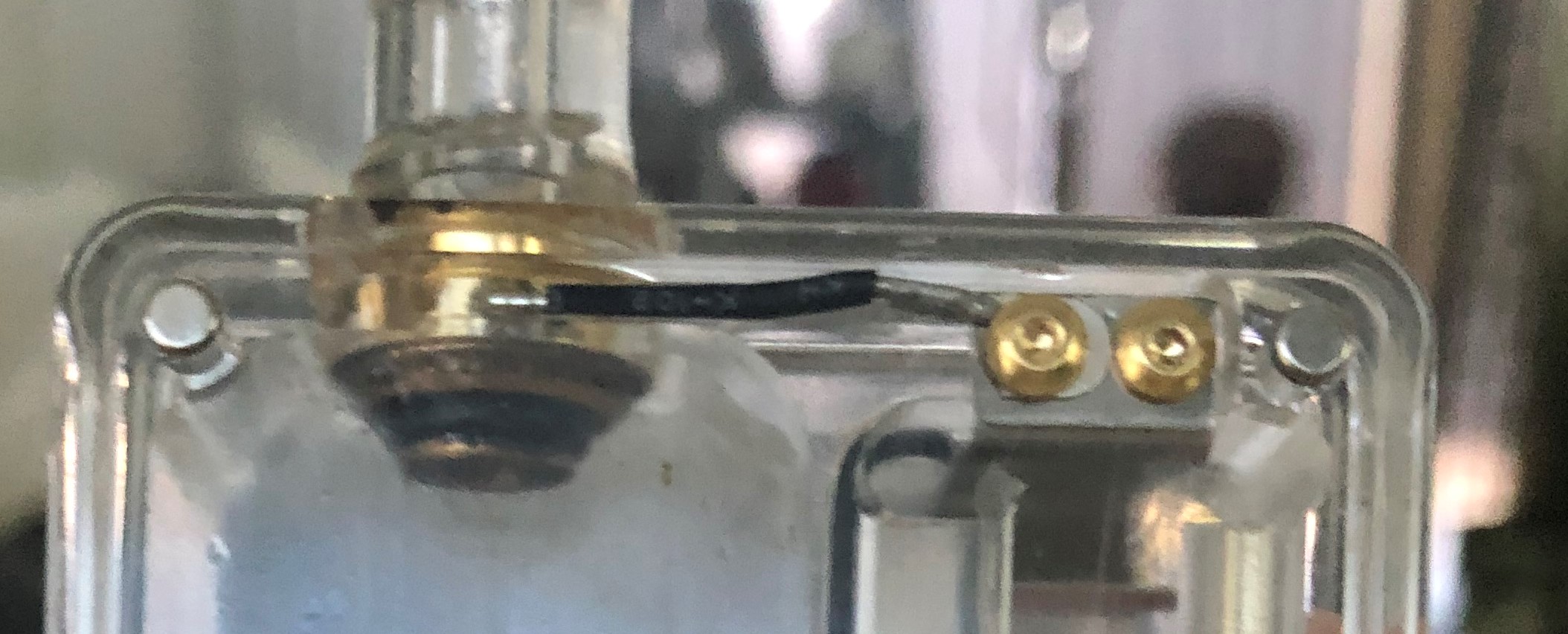

But, alas, 3d printed plastic is non-conductive. So, I am looking for a threaded insert that can be used to sctew the nut into. This insert can have a wire soldered to it to close the circuit. This is how the plastic SXK BBs do it. Like so:

I am looking for a source for the insert. Billet box threading is 1/2"-20. Preferrably in brass. It is very very thin. Coil inserts likes Helicoil tend to be very thick and too long for this purpose. The SXK one pictured above appears to be flanged at the top.

Does anyone know where to get such an insert or have any other suggestions?

Thank You!

--tom

Been playing with Autocad Fusion and my 3d printer and have been designing some hybrid billet box/Aspire boxx type designs using 21700 batteries. The original and clone billet box is aluminum and uses the chasis for ground so screwing in the "nut" provides ground for the atomizer. Pretty neat design the more I thought about it.

But, alas, 3d printed plastic is non-conductive. So, I am looking for a threaded insert that can be used to sctew the nut into. This insert can have a wire soldered to it to close the circuit. This is how the plastic SXK BBs do it. Like so:

I am looking for a source for the insert. Billet box threading is 1/2"-20. Preferrably in brass. It is very very thin. Coil inserts likes Helicoil tend to be very thick and too long for this purpose. The SXK one pictured above appears to be flanged at the top.

Does anyone know where to get such an insert or have any other suggestions?

Thank You!

--tom