Oh Fuck, Ed's joined us.. now we're d00med.

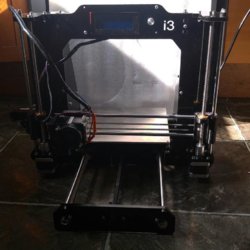

Also, I may have a 2nd printer coming.. That Prusa i3 I linked off earlier, couldn't resist it. Also considering there's no-one I know of producing 3D printed sleds in the UK, I'm looking to start producing them en mass once the Prusa arrives..

I've now got ABS printing awesomely, admittedly, the 8 hour print I left running last night when I went to bed failed so hard, it looked like a Masochist's Fleshlight. If any of you have an account on Thingiverse, look up AxMod, there's a few designs there for the CTC/Makerbots that I've been playing with. Also that 1590B shim that I've been playing with, although I forgot to drop the groove on the top, so I can't put a lid on (D'oh).

Filiment wise - I've just got a colorFabb_XT sample in, and it's so simple to print with, it needs a lot of heat (250c), but it flows beautifully. I do have some adhesion issues with it atm, 2 fails of a small model I'm testing with with a small footprint. Just needs a bit more heat on the bed I think.

Ed, we need to get together now and swap filament samples!!! I also need more space. My living room looks like a Bomb's hit it, considering it's my Living area, Office, & workshop and it's not much more than 20' -25' square you can imagine what it looks like with my stock in. In have some space at

manabush HQ which I'm moving to soon, but it looks like I'm doing it sooner than later..